The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, superfine pulverizer, pulverizer and matching hammer crusher, etc.

08/08/2022 admin

At present, there are many kinds of stone materials that can be used for sand making in the mining industry, at least 200 kinds. Basically, as long as the added value is not high, ores with a water content within a certain range can be used to make sand, including tailings from beneficiation. So, what kind of material can be made into machine-made sand? What is the process of sand making production line?

1. River pebble, basalt, granite, limestone, bluestone, iron ore, etc.

These are ideal green building materials with a hard texture. They can be used as raw materials for sand and gravel production lines. Sand made of basalt mixed with retarded concrete reduces the weight of the concrete and provides thermal and acoustic insulation. It is a good aggregate for lightweight concrete in high-rise buildings. The stone powder produced by crushing lime and granite can also be reused. These are better alternatives to natural sand.

2. Sandstone, quartz sandstone, etc.

Sandstone is a sedimentary rock composed mainly of quartz and feldspar. It is one of the good raw materials for strength and particle shape. In addition, it has become one of the good building decoration materials because of its advantages of outdoor weathering, moisture resistance and sound absorption.

3. Tailings, slag, construction waste, etc.

These exist as industrial wastes at first, but they are also “treasures” after reprocessing, such as construction waste concrete blocks, crushed stones, bricks are often used to crush sand and gravel aggregates, construction, roads and other industries, and use them as raw materials to produce machine-made sand The investment cost of raw materials can be saved. It can be used as raw materials for sand making: construction waste, waste bricks, gravel, etc.

1. The compressive strength of the raw materials used for the production of machine-made sand should not be lower than 80 MPa, and the materials should not be acidic or alkaline, and clean and hard raw materials should be used.

2. In the selection of mines, avoid the use of mines with poor quality such as thicker covering soil, more mud in the interlayer, and stratified rocks.

3. The raw materials of the exposed rock layer are selected, such as the covering soil layer or the weathered layer, which should be removed in time.

1. More than 200 tons per hour

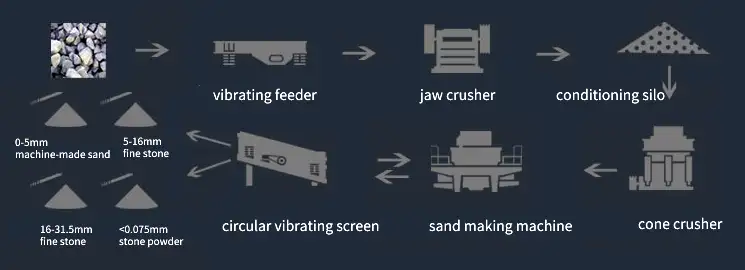

Configuration equipment: vibrating feeder, jaw crusher, cone crusher, impact sand making machine, sand washing machine, vibrating screen, conveyor belt, etc.

For hard materials, jaw crushing + cone crushing is one of the most efficient combinations. The reason why the impact crusher is configured is because the content of aggregate needle pieces after cone crushing is high. After the impact crushing treatment, the particle size of the material is uniform and the crushing effect is good. In addition, the sand washing machine cleans and removes impurities, the finished product is clean, and the market is better.

2. The output is less than 200 tons per hour

Configuration equipment: feeder, jaw crushing, compound crushing (roller crushing, double-stage crushing), vibrating screen, conveyor belt.

As a kind of initial crushing, jaw crushing can undoubtedly be crushed at 1200 mm. Jaw crushing can handle a wide range of materials, general ore can be crushed, and the output can be between 1-2200 tons. Users can choose according to the actual process.

Compound crusher, double-stage crusher and roller crusher are all small crushing and sand making equipment. The output design is relatively small, generally below 100t/h, with low power, energy saving and small footprint, and is suitable for small stone factories.

With the increasing scarcity of natural sand resources, artificial sand is bound to replace natural sand. Compared with the difficulty of natural sand mining, its grade does not necessarily meet the requirements. The machine-made sand material is convenient and the production process is scientific, which is in line with the construction sand.

If you have some questions about our products, please feel free to fill out the form below, and we will contact you within 24 hours.